Product Introduction

With increase of waste water treatment plants and development of waste water treatment technology, there are more and more sludge produced during waste water treatment process. Although there existing many disposal methods, like thermal drying, composting and incineration, basic investment and running cost are pretty high. Meanwhile, by-products with high pollution like dioxin will be produced. Calcium alkaline method can realize sludge drying, solicitation and bacterium elimination with low investment cost, quick result and stable disposal effect. This method is more suitable for further treatment of dewatered sludge from small and medium sized waste water plants.

Sludge Plus Calcium Alkaline drying craft is a kind of stable method developed by Taida Company by learning domestic new technology. This method is a kind of stable resource recovery way which makes use of additive agents to deal with municipal sludge from waste water plants. During disposal process, quick lime will be used as additive agent, stabilization agent and heating agent. After drying, dewatering and modification, sludge can be reused as stable inorganic materials. Dried products can replace auxiliary materials in construction industry and be used to make bricks to realize sludge recycling aim. This technology is characterized by no second pollution, high safety level, low investment cost and resource recycle. Calcium hydroxide will become calcium oxide after dehydration. According to this principle, after disposed matters calcined by high temperature, additive agents can be reutilized. Raw materials’ reuse aim comes true.

According to depth of process, it can be divided into three kinds:

① Primary drying by adding lime to sludge: this process continuously and efficiently mix certain amount of sludge and lime. Moisture of sludge can be reduced to below 30%.

② Secondary-class drying by adding lime to sludge: this process feeds sludge from primary process to specially designed rotary dryer. Compared with first process, this process holds higher overload strength, higher output capacity and stable effect.

③ Third-class drying by adding lime to sludge: this process is based on previous two steps. For further drying aim, sludge will mix with precisely fed cement through double-shaft mixer.

Taida has multiple running sites in this fields and helps many municipal waste water treatment plants to solve waste water disposal difficulties.

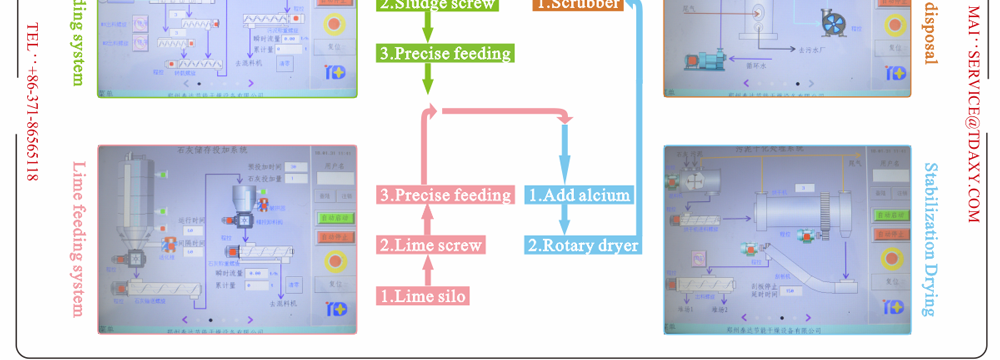

Taida sludge plus calcium alkaline drying system process flow chart:

Taida sludge plus calcium alkaline drying system core working principle:

Basis principle:

Mix sludge with fine lime uniformly, following chemical reaction between lime and moisture in sludge.

1kgCaO+0.32kgH2O---->1.32 kgCa(OH)2+1177kJ

According to this reaction, there will be 0.32kg water combined into calcium hydroxide for feeding 1kg calcium oxide. Heat produced from this reaction can evaporate about 0.5kg water. Quick lime reacts with water and produces calcium hydroxide. After this reaction, quick lime will further react with heavy metal in sludge and other compound matters. Final result is:

★Further dewatering process: Moisture is reduced to 20% to 65% from 80% to 85% (decided according to lime amount).

★kill bacterium, rise of temperature of PH value has bacterium elimination function, which can guarantee sanitary safety during utilization and disposal process.

★passivate heavy metal ions, add certain amount of calcium oxide to make sludge alkaline. Partial metal ions in sludge will combine with lime and form harmless compounds to reach heavy metal ions passivation aim.

★modification and granulation, improve storage and transportation condition; Avoid secondary fly ash and leak of leachate.

★semi-dry and solidification, effectively reduce moisture content, provide convenience for reutilization and landfill.

★Because moisture is evaporated, although extra amount of lime is added to whole system, system total weight doesn’t increase too much.

Dry sludge application after sludge plus calcium alkaline method:

After moisture is dewatered to 30%, can volume be reduced further?

After adding calcium process disposal, sludge moisture can drop to about 30% sharply. Moisture level can be reduced further after stacking. Organic matter content can be reduce to 8% from 45% and TN content will drop to 1%. E. coli and fecal coli can be completely eliminated.

Many customer may have higher requirement for final moisture. Aimed at this demand, besides adding calcium alkaline method, Taida can also provide medium-temperature drying system. For example, Taida TDOSC series air swept rotary wing dryer can reduce sludge moisture to below 5%. Both weight and volume of sludge can be decreased by 80%. Please contact Taida sales person for details.

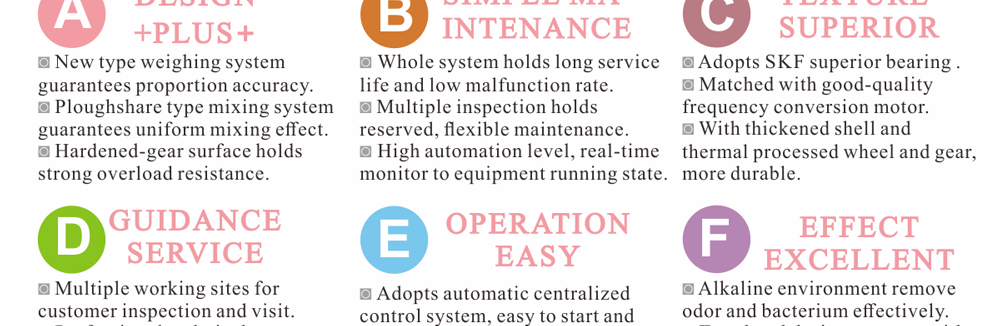

Product Superiority

Adding calcium to sludge process makes use of the reaction between quick lime and water. Owing to this reaction, high temperature and high alkaline environment will be formed. While evaporating moisture and realizing deep dehydration aim, harmful pathogen and bacterium will be killed. Partial heavy me

|

Moisture <50% |

Passivation function to 9 kinds of heavy me |

3 months |

|

Sterilization rate >99.99% |

Reaction temperature is 55 to 80 degrees, fully kill bacterium |

|

|

100% closed system, fully collect all waste gas, effectively eliminate odor. |

||

△ Adding calcium stable drying technology can kill bacterium and remove odor.

△ Equipment input capacity range is flexible, from 100kg/h to tons per hour.

△ Reaction temperature is as high as 50 to 80 degrees, has passivation function to 9 kinds of heavy me

△ Low investment cost, less occupation area, short construction period.

Working Principle

Sludge plus calcium alkaline drying system working principle and work process

Whole set system is composed of:

1. Lime precise dosing system: precisely toss quick lime in silo to quick mixing system.2. Sludge storage and weighing conveying system: send dewatered sludge to quick mixing system after continuously weighing.

3. Quick mixing system: water in sludge will react with quick lime and fully mix. This reaction is exothermic reaction. On one hand, water in sludge will be evaporated. On the other hand, alkaline and high temperature environment can kill harmful bacterium.

4. Rotary drying system: disperse and break lumps formed in quick mixing process, make raw materials fully react with lime.

5. Tail gas disposal system: mainly consists of corrosion-resistant fan and scrubbing tower; can effectively remove odor and reduce dust content.

Technical Parameter

|

Input capacity |

Power/kw |

System area occupation/m2 |

Notes |

||

|

Running power |

Installed power |

Core equipment area |

System area |

||

|

1t/h |

17.5 |

30 |

20 |

90-125 |

provide complete, systematic technology and product service. |

|

2t/h |

22.5 |

40 |

24 |

125-175 |

|

|

3t/h |

30 |

50 |

32 |

175-300 |

|

|

4-5t/h |

45 |

70 |

48 |

300-400 |

|

|

7.5t/h |

55 |

90 |

60 |

350-450 |

|